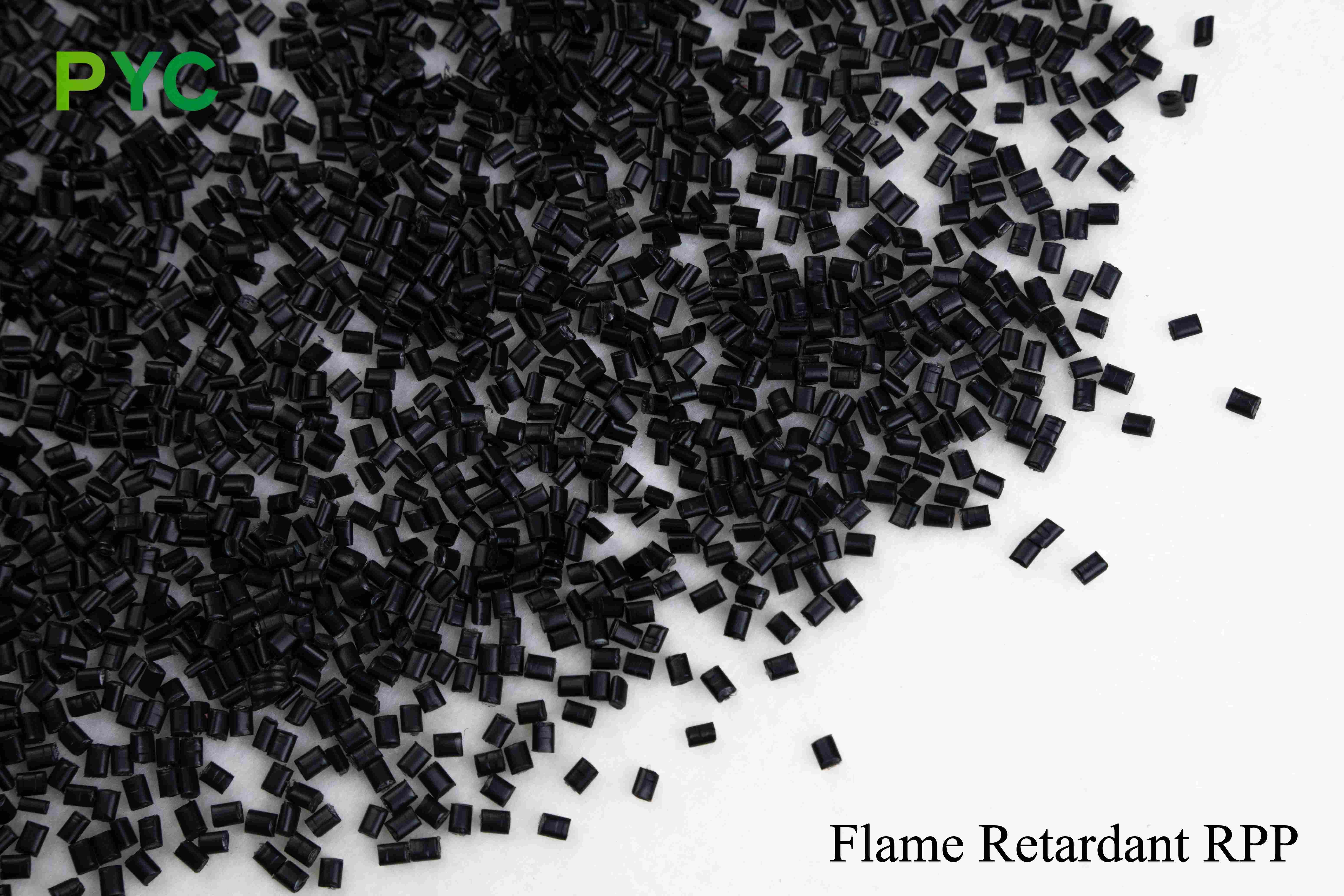

Flammhemmendes RPP

High quality recycled raw materials

Flame Retardant RPP (Flame Retardant Recycled Polypropylene) uses a single source, highly screened industrial recovered Flame Retardant PP (Flame Retardant PP) raw material, the main sources include the following specific recycling channels:

Automotive and transportation components: automotive dashboards, interior trim, battery dividers, automotive cable sheathing, etc. These components use flame retardant modified PP to ensure good fire resistance in a fire environment. When recycling, the raw materials are broken, cleaned, removed impurities, molten granulation and other processing to ensure that the material has efficient flame retardant and stable physical properties.

Home appliances and electronic equipment housing: mainly including electrical housing (such as refrigerator, washing machine, air conditioning), TV back cover, power tool housing, power adapter, etc. Most of these products use flame retardant modified PP, in the recycling process after screening, purification, melting treatment to ensure that it has good flame retardant and processing performance.

Construction and electrical applications: including electrical equipment shell, socket panel, cable jacket, building materials (such as flame retardant sheet), etc. These products are often used in the application field that requires flame retardant characteristics. When recycled, they are strictly screened, melted and cleaned and re-granulated to ensure that flame retardant properties are not affected and comply with relevant fire safety standards.

All raw materials are fine screening and optimization treatment to ensure low impurity content, excellent flame retardant performance and stability, widely used in automotive parts, home appliance shell, electrical equipment, building materials and industrial products and other fields.

High efficiency flame retardant, in line with international safety standards

Flame Retardant RPP by adding environmentally friendly flame retardant, can reach UL94 V0, V2 and other different levels of flame retardant standards. Even when exposed to high temperatures, the material can effectively inhibit flame propagation and reduce smoke release during combustion, making it suitable for applications requiring high safety such as electrical housings and automotive interiors.

Maintain excellent mechanical properties, impact resistance is not easy to crack

Using advanced Flame Retardant modification technology, Flame Retardant RPP improves flame retardant while still maintaining high impact strength and toughness, and will not be brittle due to the addition of flame retardants, and can be applied to parts that bear external forces for a long time, such as home appliance shell, auto parts, etc.

It is stable in heat resistance and can adapt to high temperature environment

The material can remain stable at temperatures above 100 ° C, has excellent thermal aging performance, and can maintain good mechanical properties after long-term use in high-temperature electrical equipment, outdoor facilities, etc.

Environmental protection and sustainable, in line with the trend of green manufacturing

Using high quality recycled PP materials combined with halogen-free or low halogen-free environmentally friendly Flame Retardant systems, Flame Retardant RPP reduces the environmental impact of traditional flame retardant materials while reducing carbon emissions and meeting global sustainability requirements

Product Details:

Field of application

Electrical and electronics industry:

Suitable for electrical shell, cable sheath, socket, electrical switch box, etc., to provide good flame retardant protection, reduce the risk of fire when electrical short circuit or overload. Through UL94 V0 level test, it can work stably in high temperature and high voltage environment for a long time.

Automotive Industry:

It is suitable for automobile instrument panel, interior decoration, battery shell, wire harness sheath, etc., to improve the overall safety of the vehicle and reduce the fire risk caused by electrical failure. With good high temperature resistance, even in the high temperature exposure environment can still maintain a stable form.

Home appliance industry:

It is suitable for rice cooker shell, air conditioner shell, washing machine internal structure, etc., to ensure that it still has good durability and safety in high temperature and high humidity environment. Environmental protection and flame retardant technology is adopted to ensure that the material does not release harmful gases and meets the safety standards of green home appliances.

Construction and industrial equipment:

It is suitable for building flame retardant pipeline, exhaust system, cable bridge, etc., to improve the fire resistance of the whole building. It is suitable for industrial equipment shell, instrument bracket, power distribution cabinet, etc., to ensure the safe operation of equipment in high temperature or fire environment.

Performance advantage

Flame retardant grade up to UL94 V0 or V2, in line with international safety standards.

Excellent impact strength to avoid material embrittlement due to flame retardant modification.

Excellent high temperature resistance, can be used in the environment above 100℃ for a long time.

Environmental protection sustainable, the use of halogen-free or low halogen flame retardant system, reduce the impact on the environment.

Good processing adaptability, can be used for injection molding, extrusion and other molding processes, improve production efficiency.

Sustainable development and market prospects

As the global requirements for the safety and environmental protection of Flame Retardant materials continue to increase, Flame Retardant RPP, as a sustainable, high-performance recycled flame retardant polypropylene material, continues to grow in the automotive, electrical, home appliances, construction and other industries. In the future, the material will help companies improve product safety while achieving green manufacturing and circular economy goals.